Smart Automation Cells

Pre-engineered robotic cells designed for common industrial applications. Each cell includes robot, end-effector, safety systems, and controls—ready for installation.

100 smart cells found

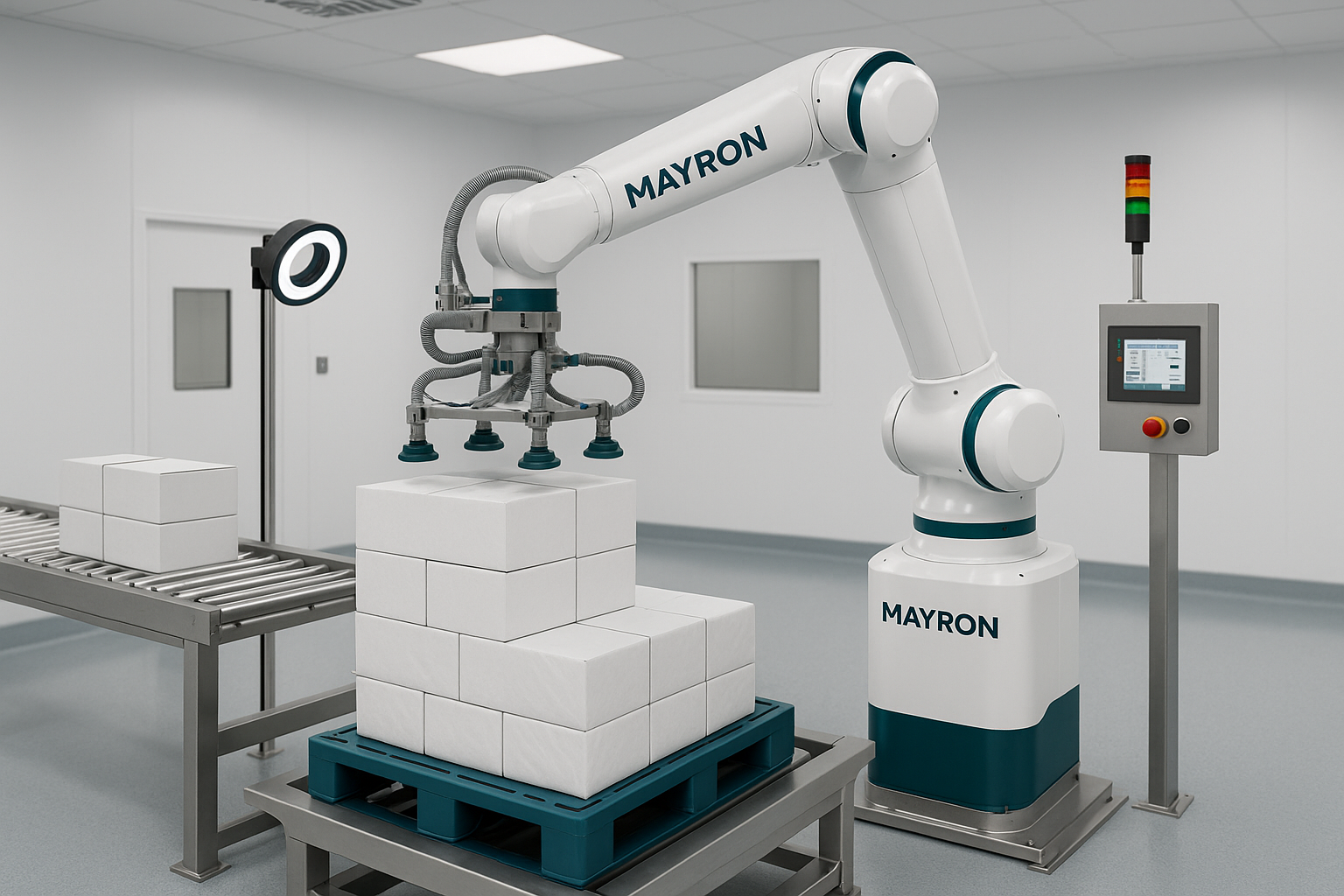

Palletizing Cell

Faster end-of-line throughput, consistent stacks, safer floors.

Depalletizing Cell

Automated layer picking with vision guidance for mixed SKU handling.

Box Erecting Cell

Automated box erection and bottom sealing for packaging lines.

Case Packing Cell

High-speed case packing with vision-guided product placement.

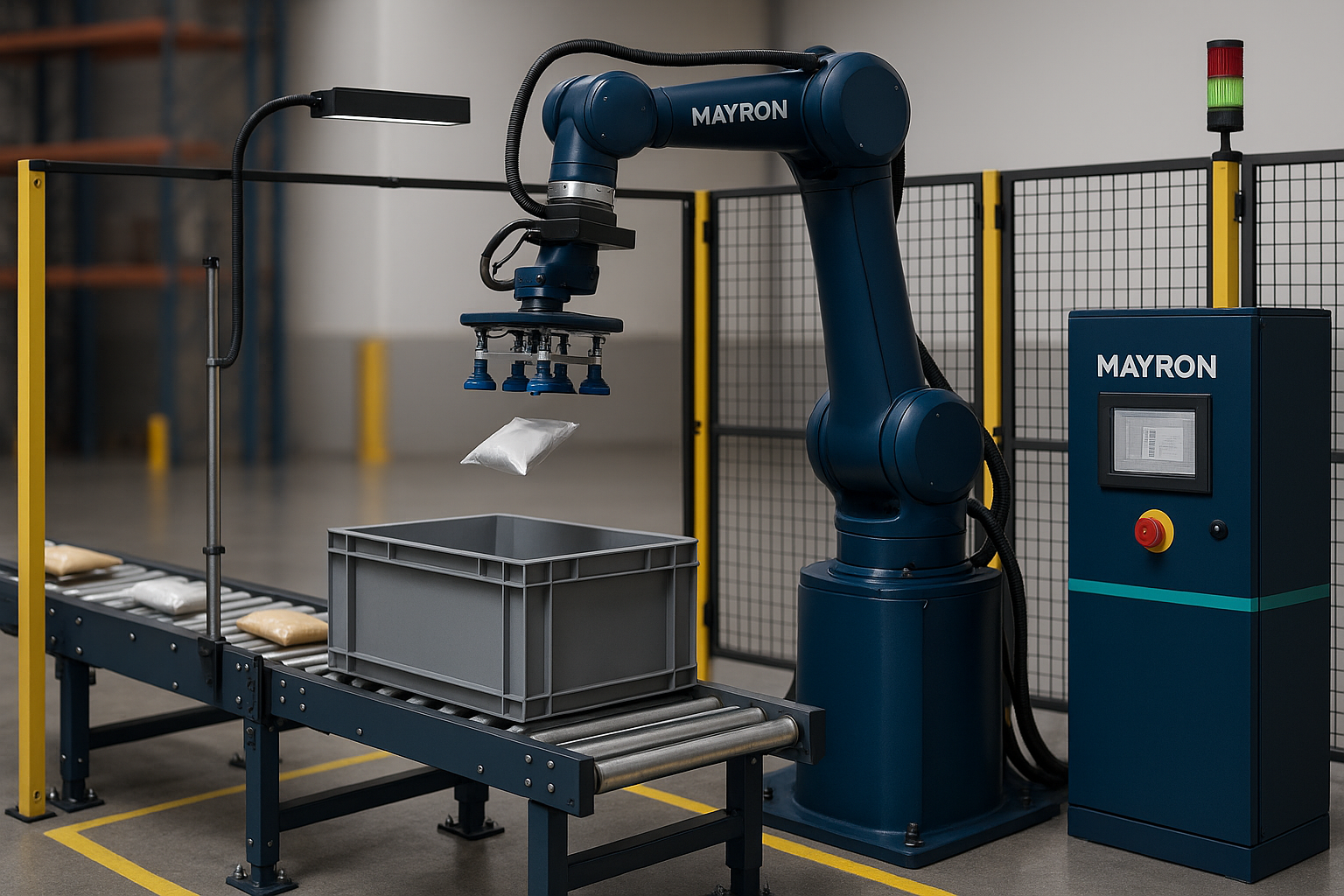

Tote Loading Cell

Automated tote loading with vision-guided product placement.

Tote Unloading Cell

Automated tote unloading with product sorting and routing.

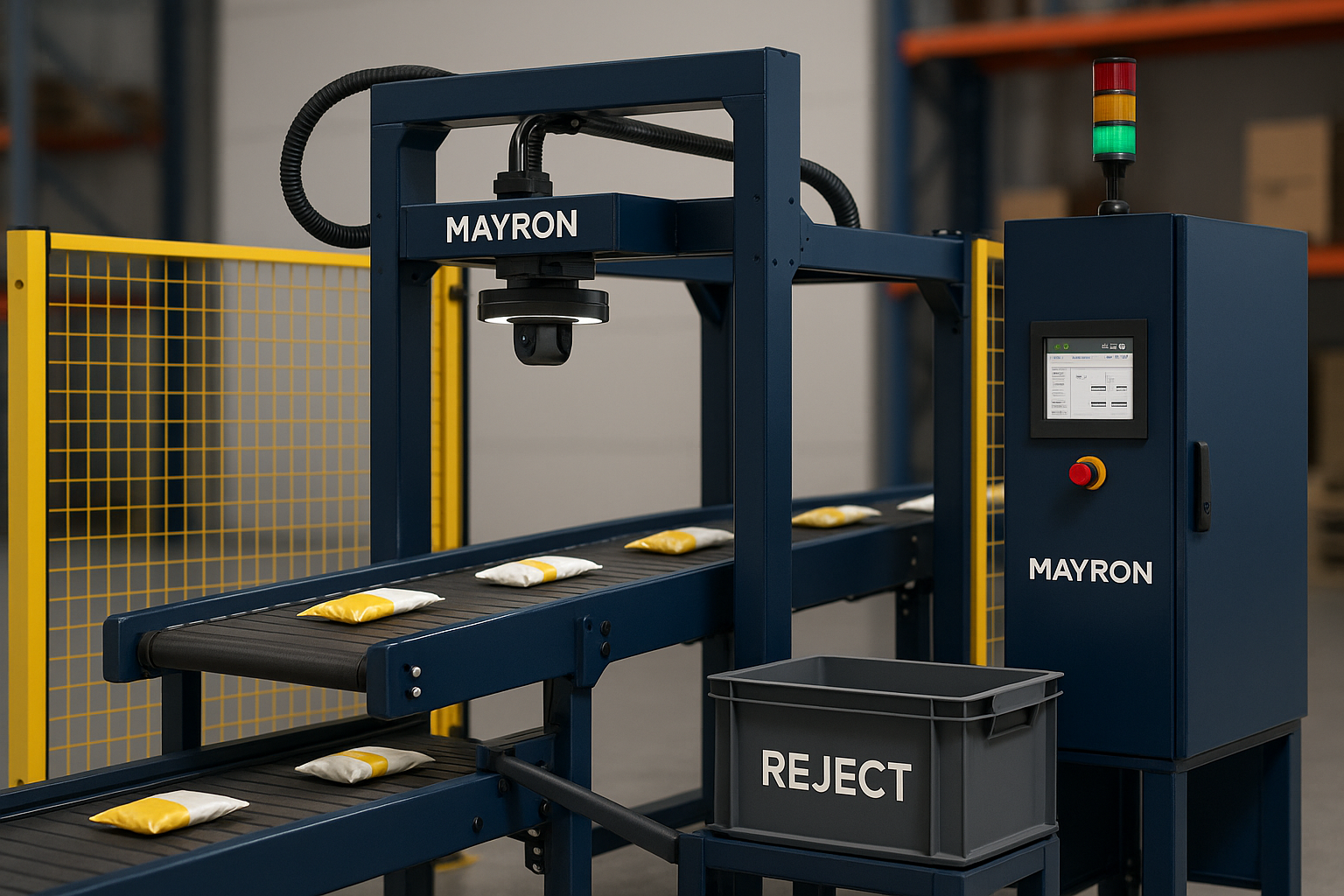

Conveyor Sorting Cell

High-speed product sorting with vision guidance and reject handling.

Mobile Pallet Mover Cell

Autonomous pallet transport with navigation and safety systems.

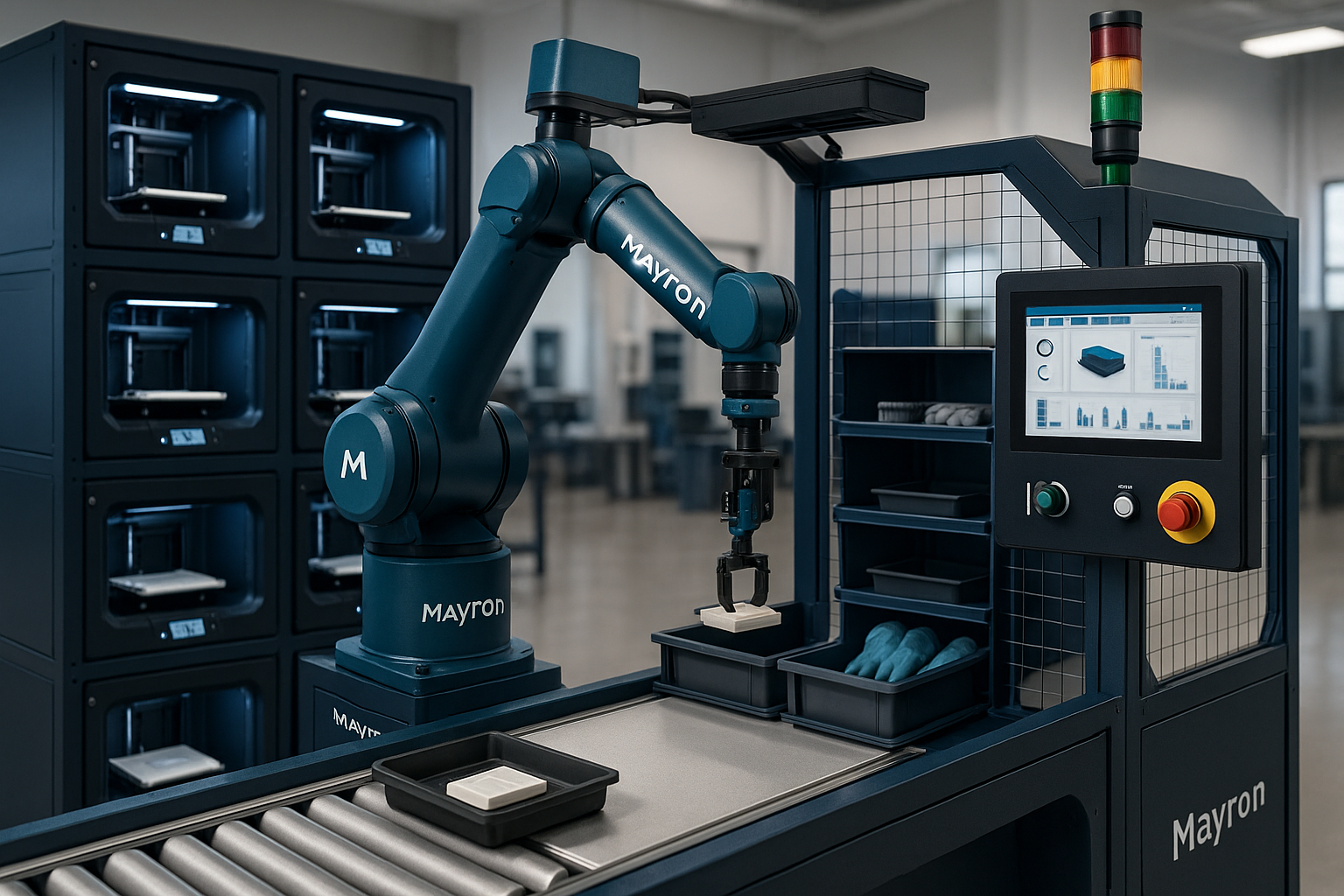

ASRS Integration Cell

Automated storage and retrieval system integration with robotic handling.

Bin Picking Cell

AI-powered random bin picking with 3D vision and adaptive gripping.

Screwdriving Cell

Precision automated screwdriving with torque control and verification.

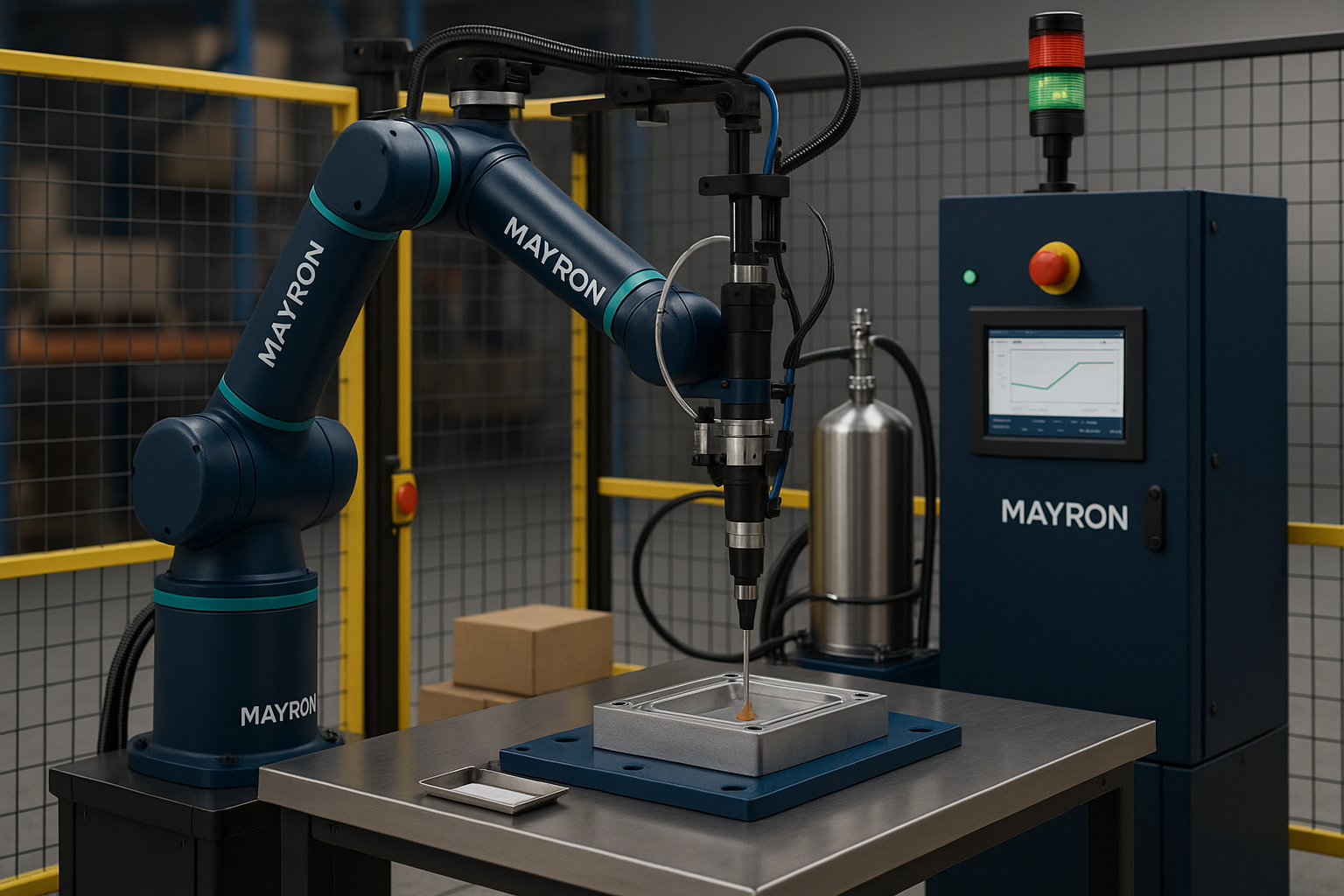

Dispensing Cell

Precision fluid dispensing with volume control and path programming.

Ultrasonic Welding Cell

Precision ultrasonic welding for plastic components and assemblies.

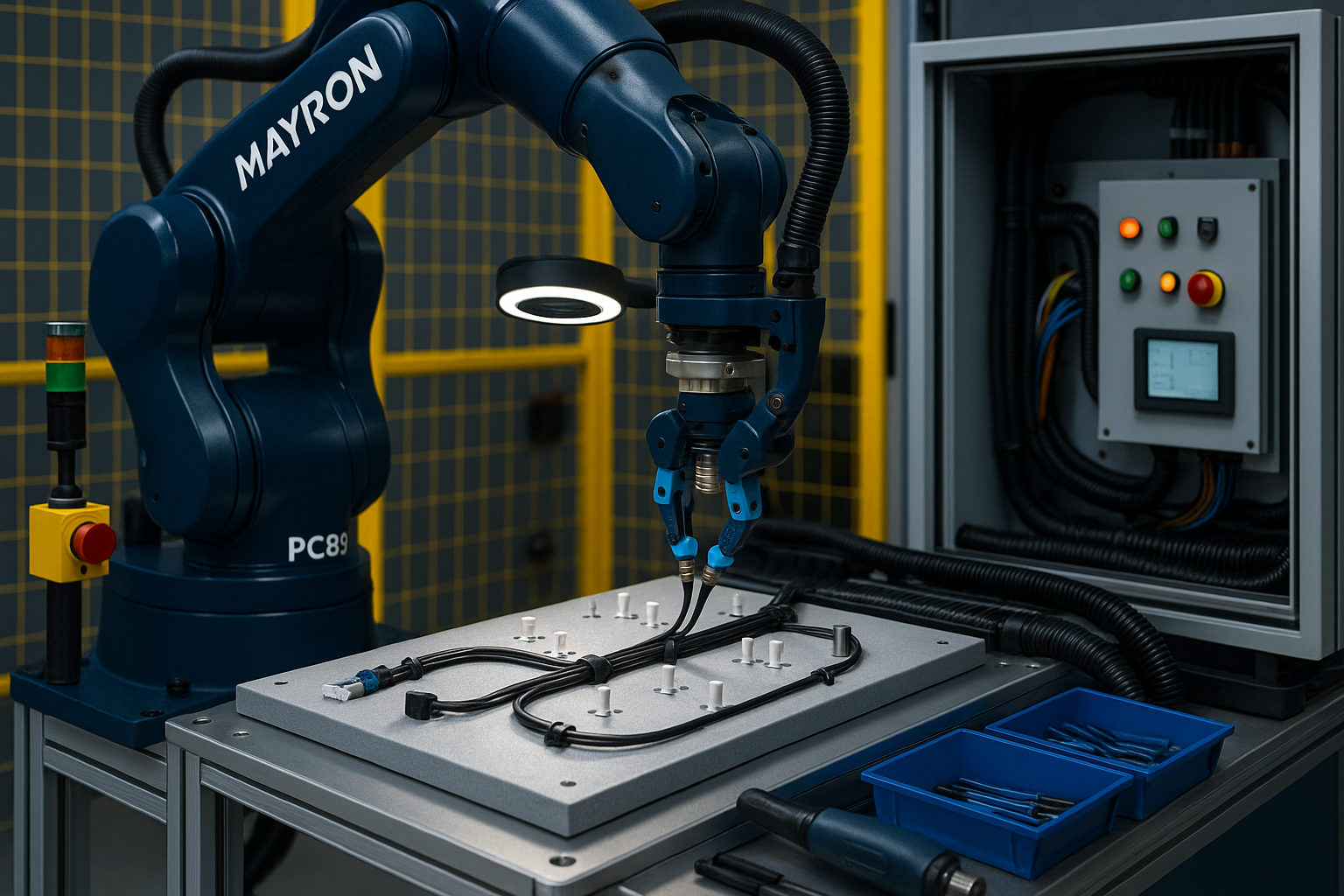

PCB Insertion Cell

Automated PCB insertion with vision guidance and force control.

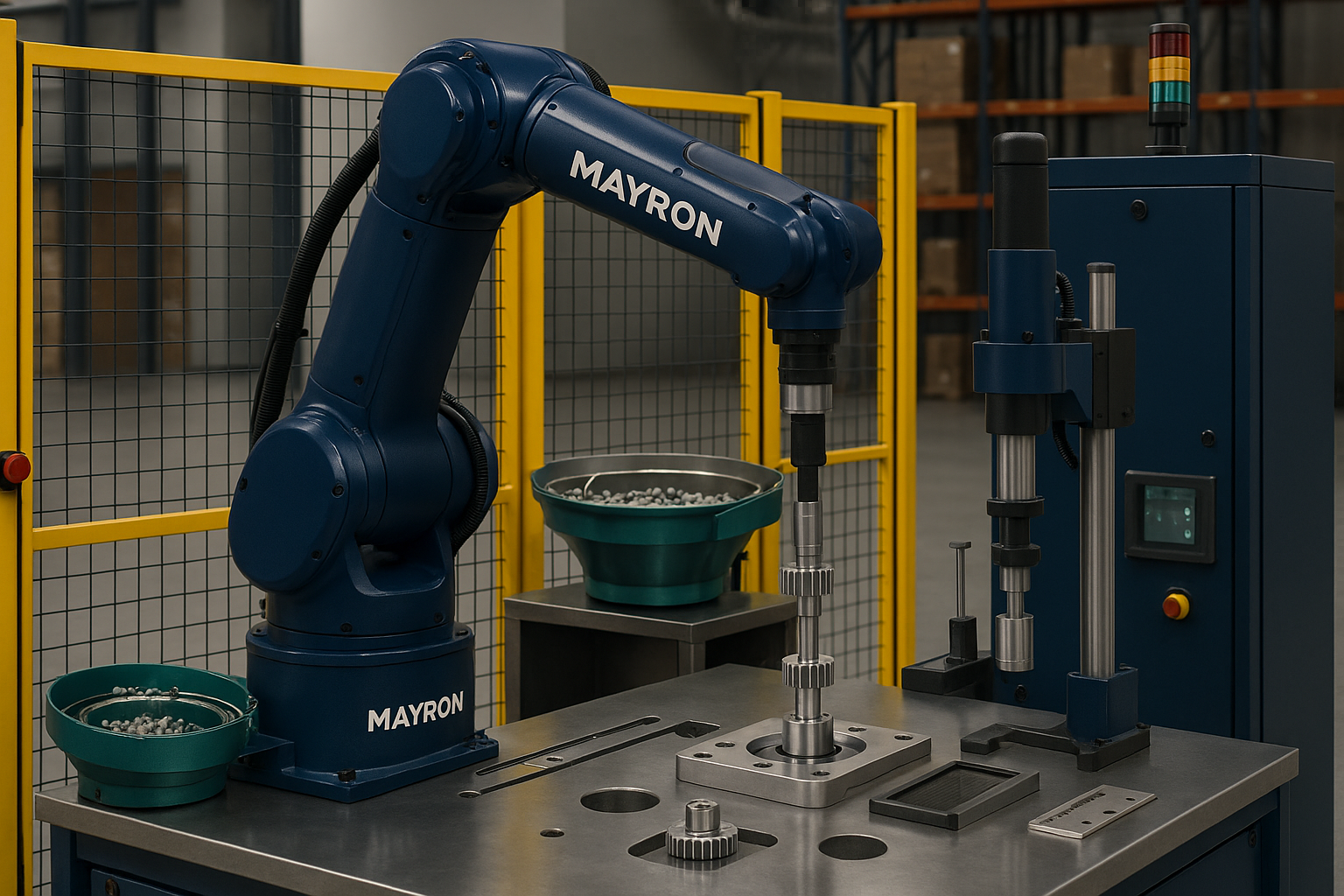

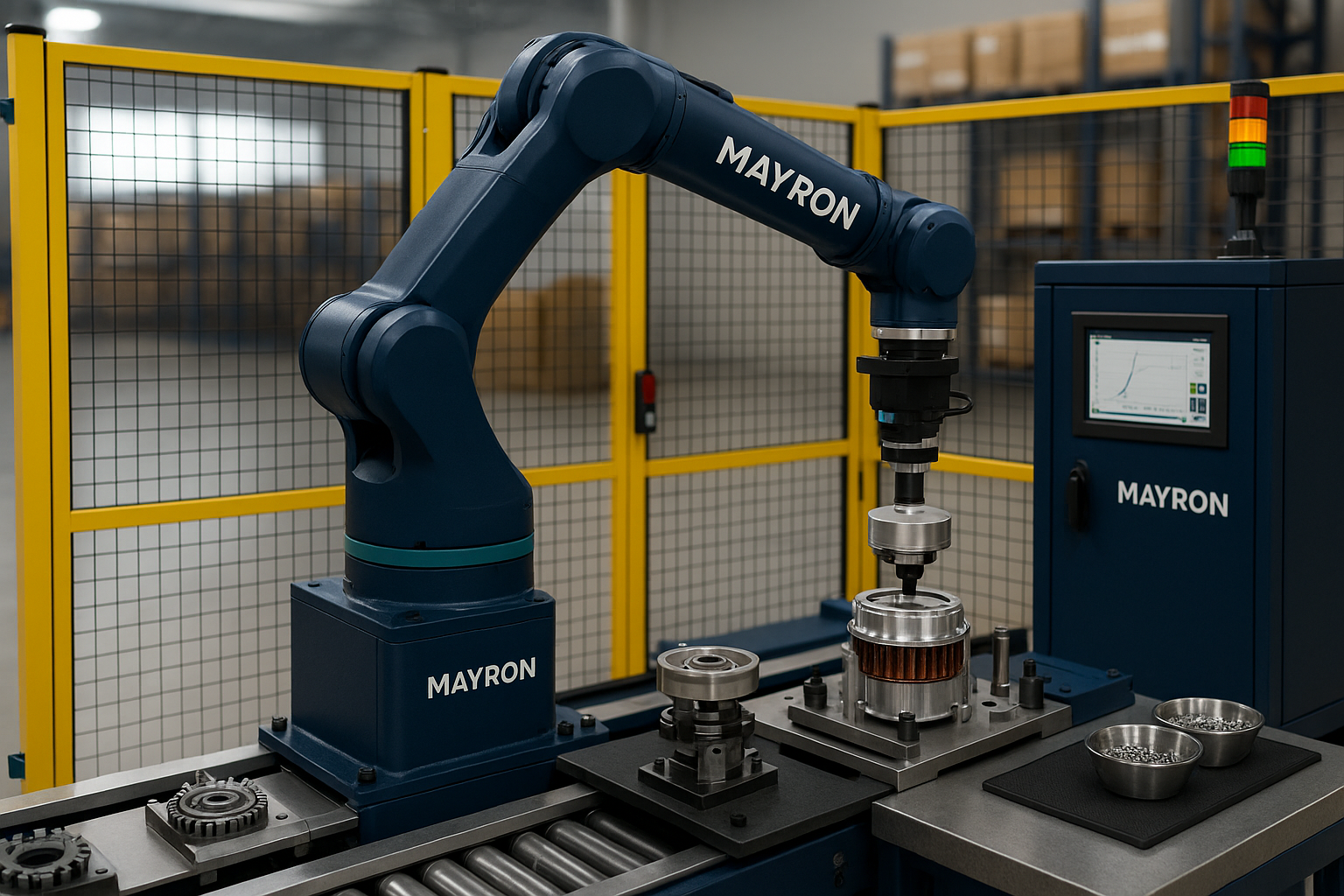

Gear Assembly Cell

Precision gear assembly with torque monitoring and quality verification.

Motor Assembly Cell

Complete motor assembly with winding, testing, and quality control.

Custom Kitting Cell

Flexible kitting and assembly with vision-guided component selection.

Fastening Cell

Multi-fastener automation with torque control and verification.

Riveting Cell

Automated riveting with force control and quality monitoring.

Magnetic Assembly Cell

Magnetic component assembly with precision placement and testing.

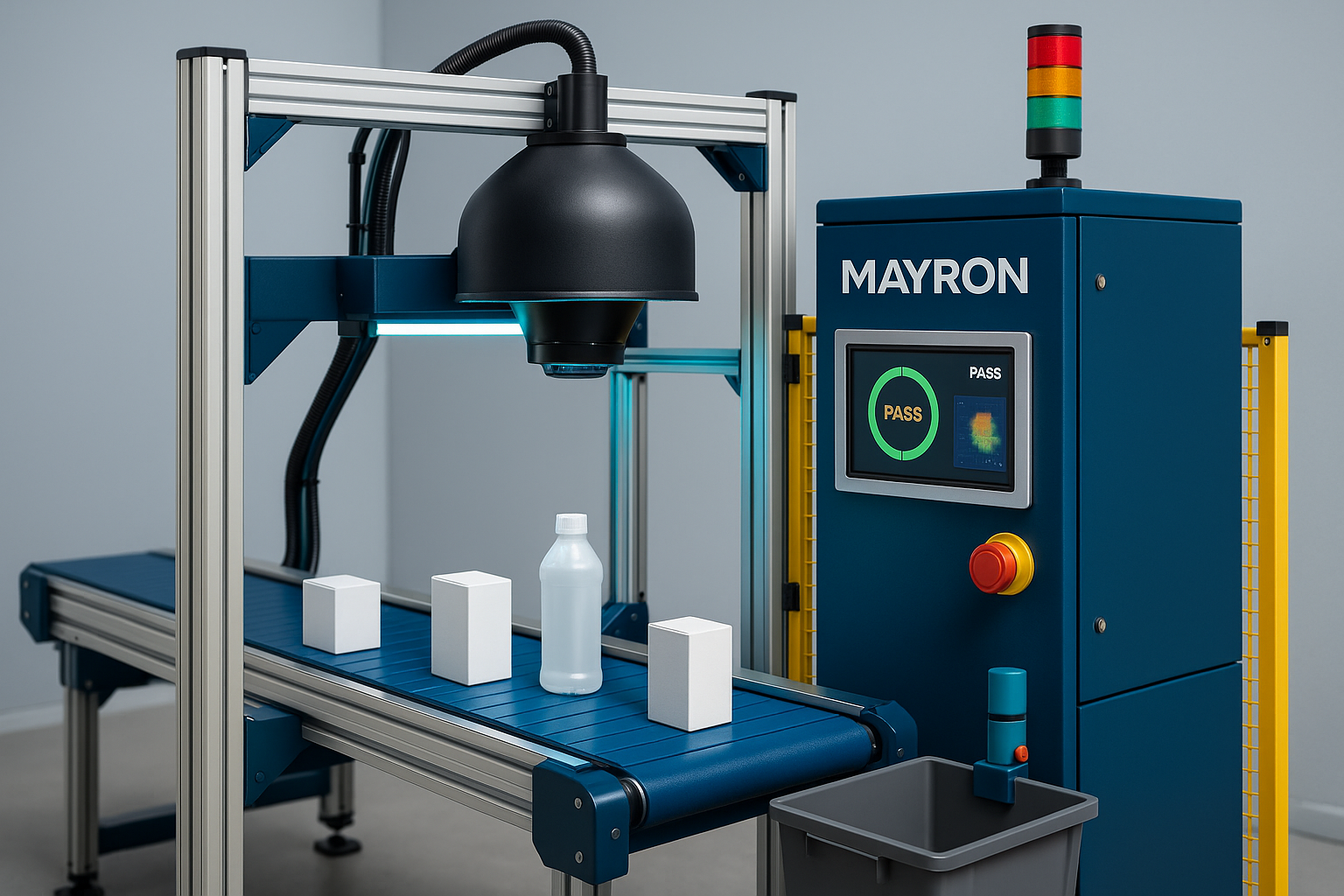

Vision QC Cell

AI-powered quality inspection with defect detection and classification.

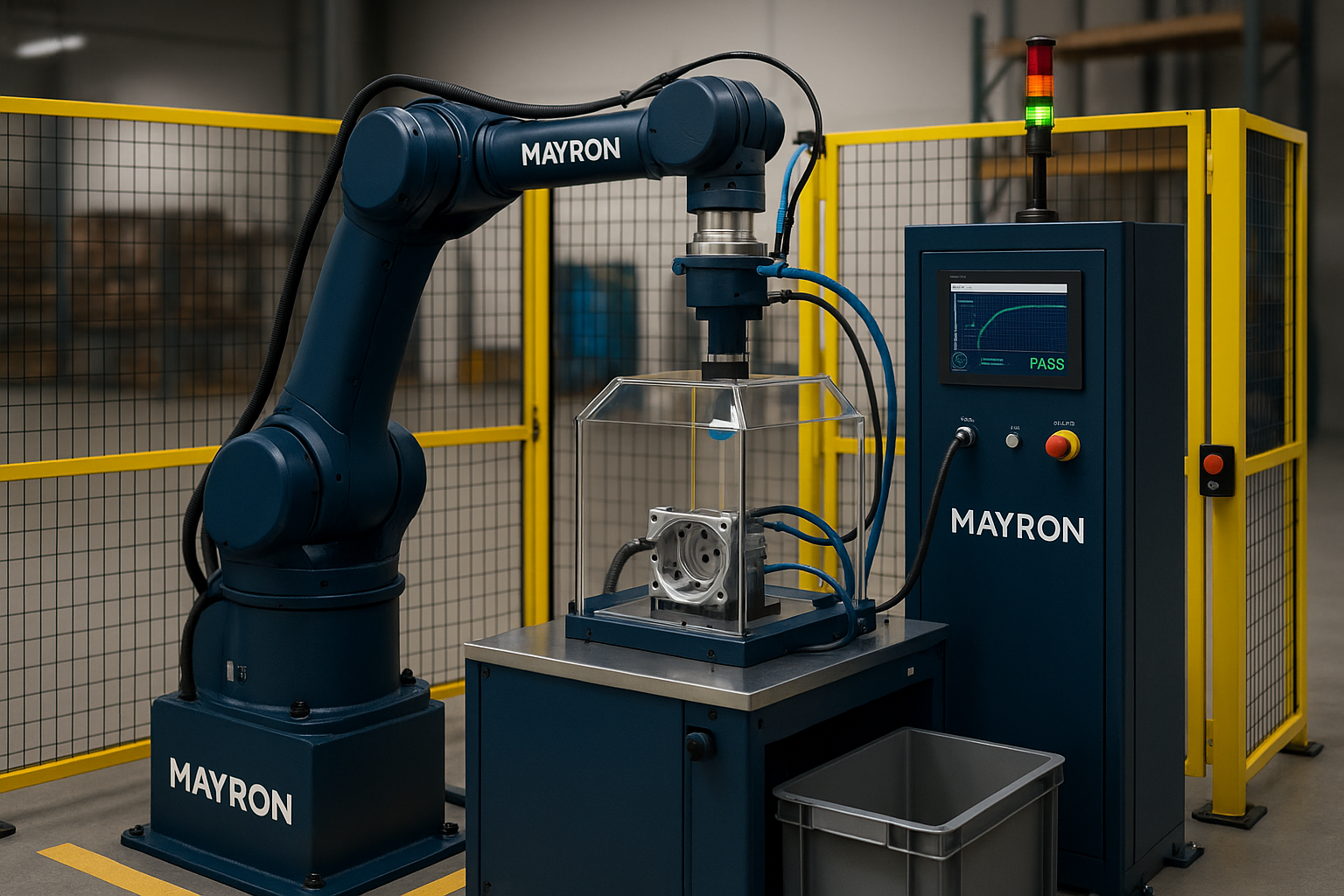

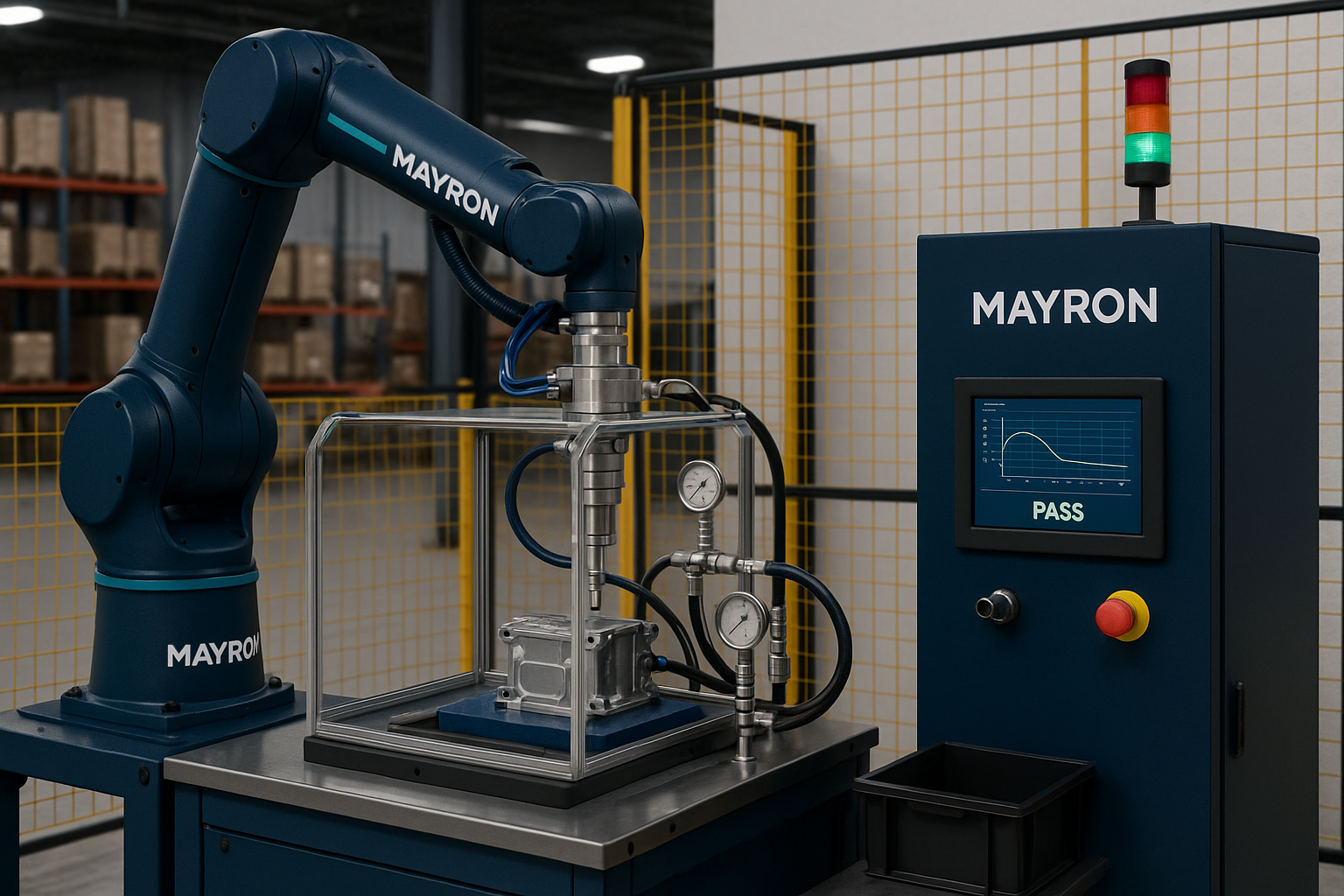

Leak Detection Cell

Automated leak detection with pressure testing and reject handling.

Weight Verification Cell

High-precision weight verification with statistical process control.

Barcode Scanning Cell

Multi-angle barcode scanning with verification and data logging.

Electrical Testing Cell

Automated electrical testing with multi-parameter verification.

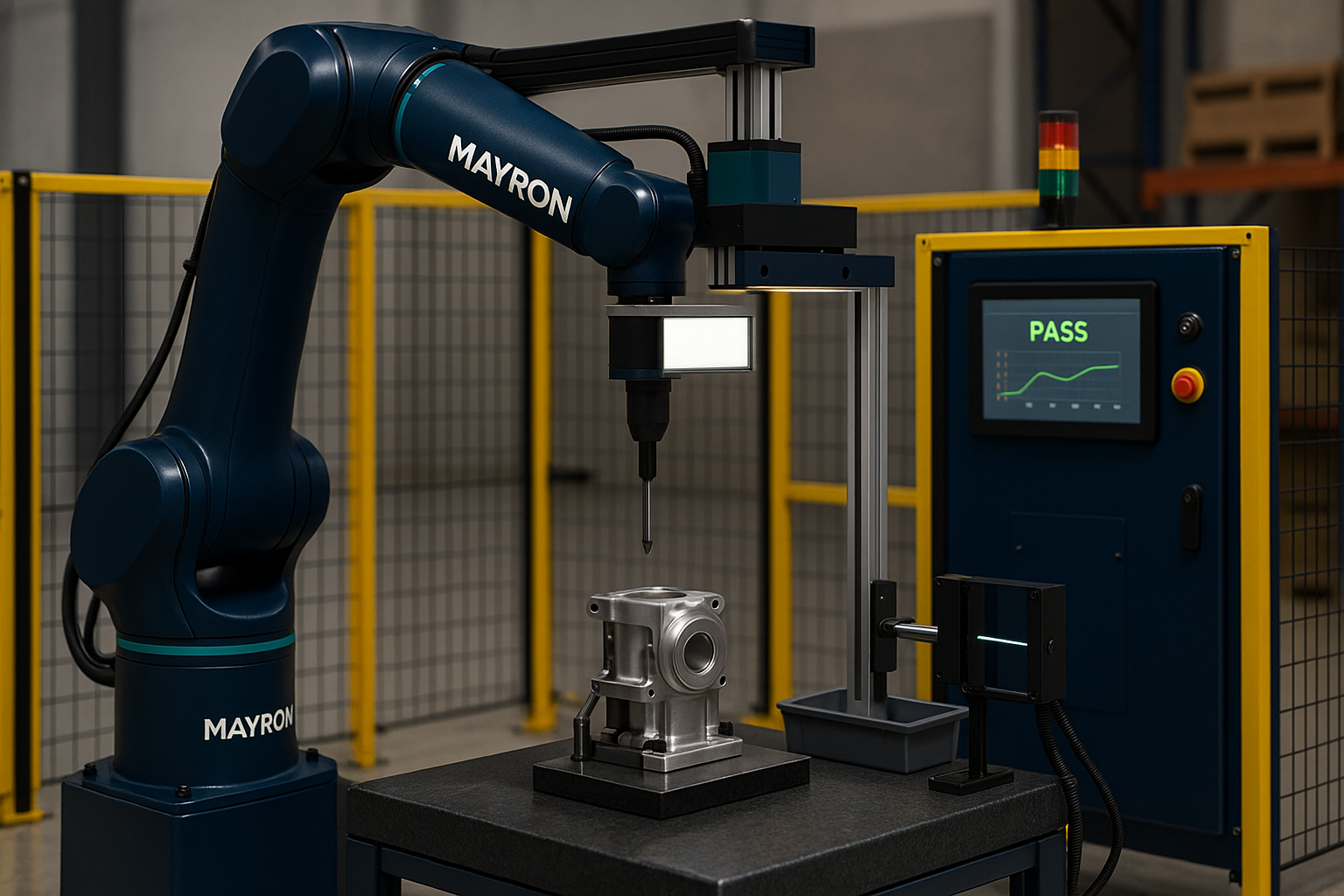

Dimensional Inspection Cell

Inline 2D/3D metrology with micron-level gauging, SPC, and automatic pass/fail sorting.

Torque Testing Cell

Automated torque and angle verification with high-accuracy transducers, traceable data logging, and error-proofing.

Pressure Testing Cell

Automated pressure/decay testing with electronic regulation, high-accuracy transducers, and full traceability for airtight, watertight, and burst validations.

End-of-Line Test Cell

Automated functional & safety testing with serialization, data logging, and pass/fail sorting for zero-defect shipments.

Static Load Testing Cell

Automated proof-load, compression, and tensile testing with high-accuracy force and displacement capture.

Microelectronics Assembly

Ultra-precision assembly for microelectronics with ESD protection.

Soldering Automation

Automated soldering with temperature control and quality monitoring.

Semiconductor Handling

Clean room semiconductor handling with ESD protection and precision placement.

Wafer Transfer

Automated wafer transfer with clean room compatibility and precision handling.

PCB Labeling

Automated PCB labeling with vision verification and data logging.

Static-Safe Handling Cell

ESD-safe robotic handling for sensitive electronics with ionization, continuous grounding, and traceable quality controls.

Cleanroom Palletizer

ISO cleanroom-rated palletizing with HEPA downflow, low-shedding materials, and recipe-driven patterns for sterile, traceable packaging.

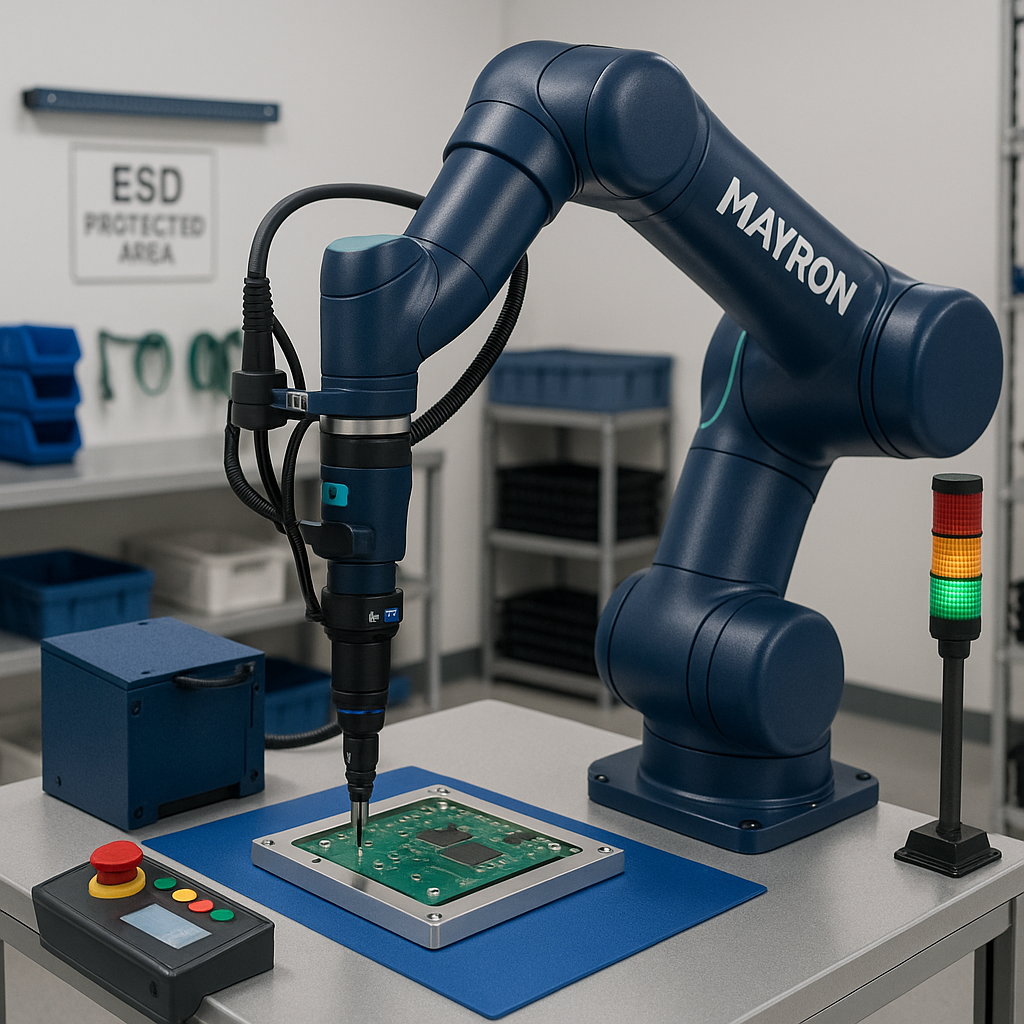

PCB Screw Cell

Torque-controlled screwdriving for PCB subassemblies with ESD protection and error-proofing.

Conformal Coating Cell

Selective conformal coating with vision alignment, multi-valve deposition (spray/film/needle/jet), and in-line UV/IR cure for clean, repeatable protection.

Circuit Board Test Cell

Automated in-circuit and functional test with boundary-scan, firmware flashing, and full traceability.

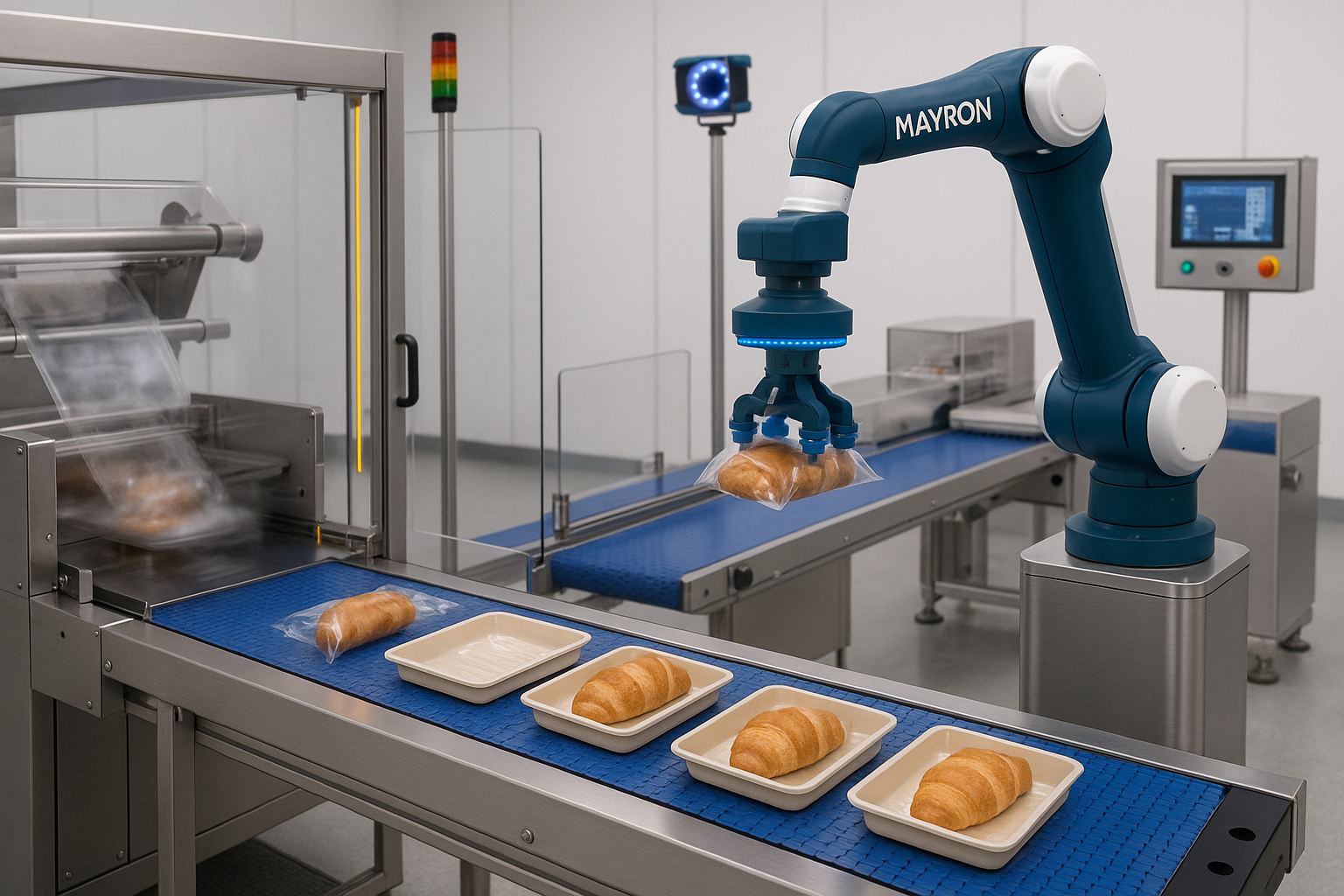

Bakery Packaging Cell

Gentle, high-speed pick & place into flow-wrap, tray, or carton with hygienic design and inline quality checks.

Beverage Handling Cell

Hygienic case & crate handling for cans and bottles with vision‑guided depalletizing, case packing, and palletizing—fast changeovers and optional washdown.

Frozen Goods Sorting

Cold-room sorting of frozen cases, bags, and trays with washdown conveyors, cold‑rated robotics, and vision tuned for frosted packaging.

Sanitary Pick & Place

Hygienic, high-speed pick & place for food, beverage, and pharma with washdown design and tool‑less teardown.

Meat Packing Cell

Automated meat packing with temperature control and sanitary design.

Pharmaceutical Labeling

GMP-ready print–apply labeling with 100% OCR/OCV verification, GS1 serialization, and automated reject handling.

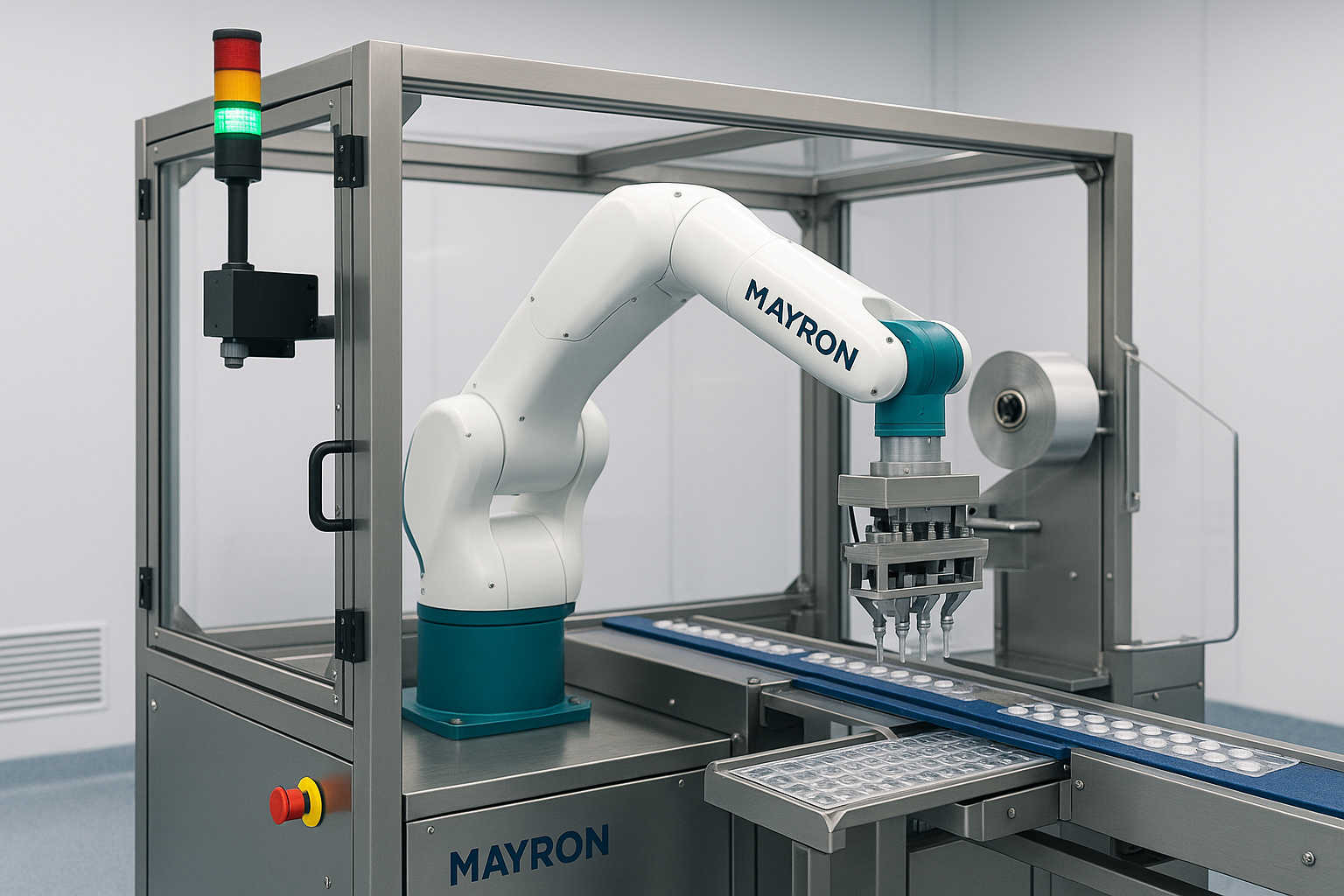

Blister Pack Loading

Fast, hygienic loading of parts into blister cavities with vision‑guided pick & place, serialization, and 100% inspection.

Vial Sorting Cell

High-speed vial unscrambling, orientation, and sorting with vision-based quality checks and CFR Part 11-ready data capture.

Cold Chain Palletizing

High‑throughput palletizing in refrigerated and freezer environments using cold‑rated robotics and hygienic materials.

Nutraceutical Packaging

Sanitary, high-throughput packaging for supplements with inline counting, labeling, and full traceability.

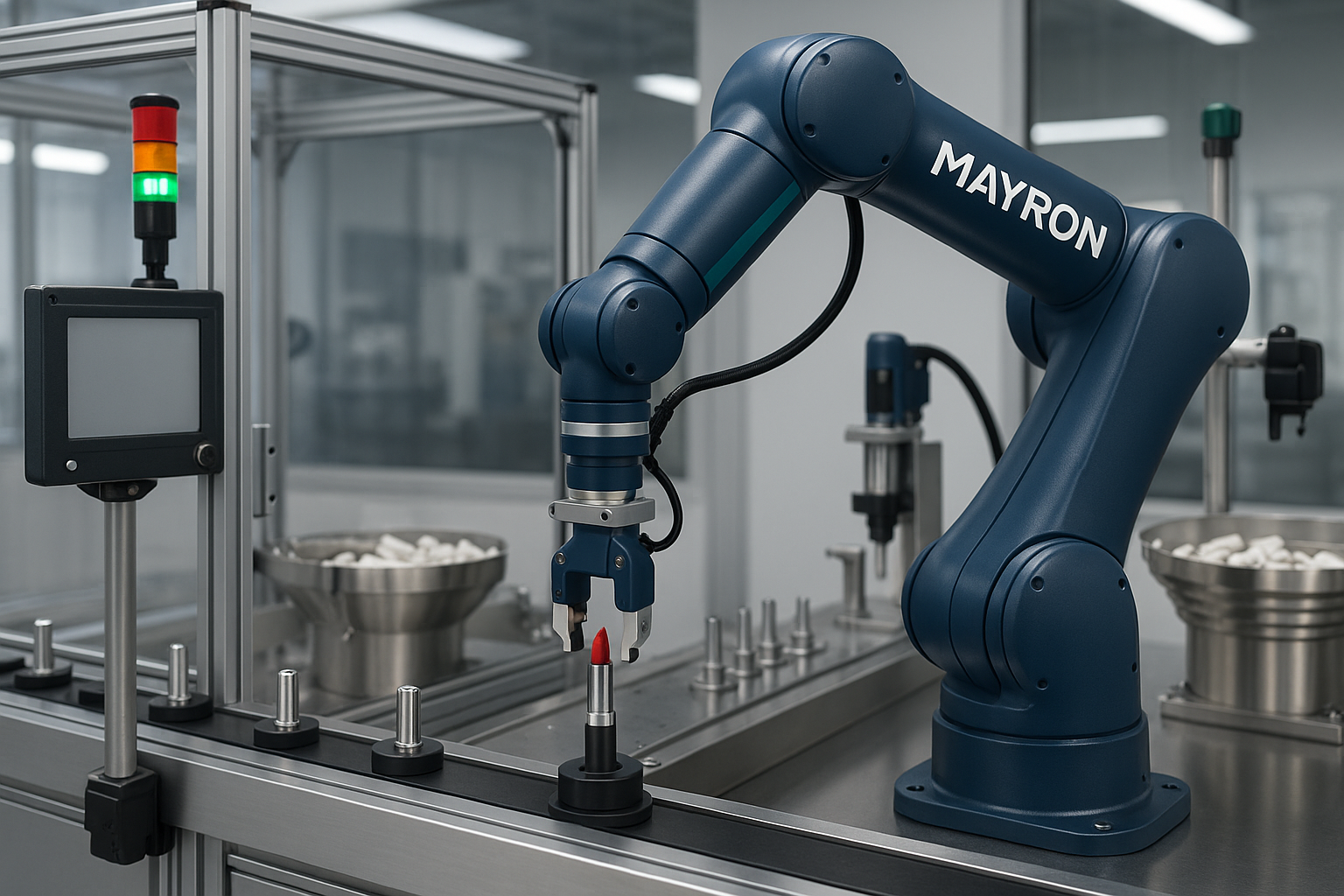

Cosmetic Assembly

High-speed cosmetic assembly with gentle handling, torque-verified capping, label verification, and full batch/lot traceability.

Bottle Capping

High-speed bottle capping with servo-controlled torque, cap orientation, and in-line inspection for consistent, leak-free seals.

Pouch Filling Cell

High-speed pouch filling for powders, granules, or liquids with recipe-driven changeovers and integrated sealing & verification.

Candle Packaging

Gentle, glass-safe candle packaging with auto-cartoning, print-verify labeling, and inline quality checks.

Toothpaste Box Loading

Automated loading of toothpaste cartons into cases or display trays with gentle vacuum handling, vision alignment, and recipe-driven pack patterns.

Blister Inspection

100% inline blister inspection with deep-learning vision: missing/broken product, color mix-ups, foil/seal defects, lot/expiry OCR—and verified auto-reject.

Label Placement Cell

High-speed label application with vision verification, print-and-apply options, and in-line reject for zero-miss traceability.

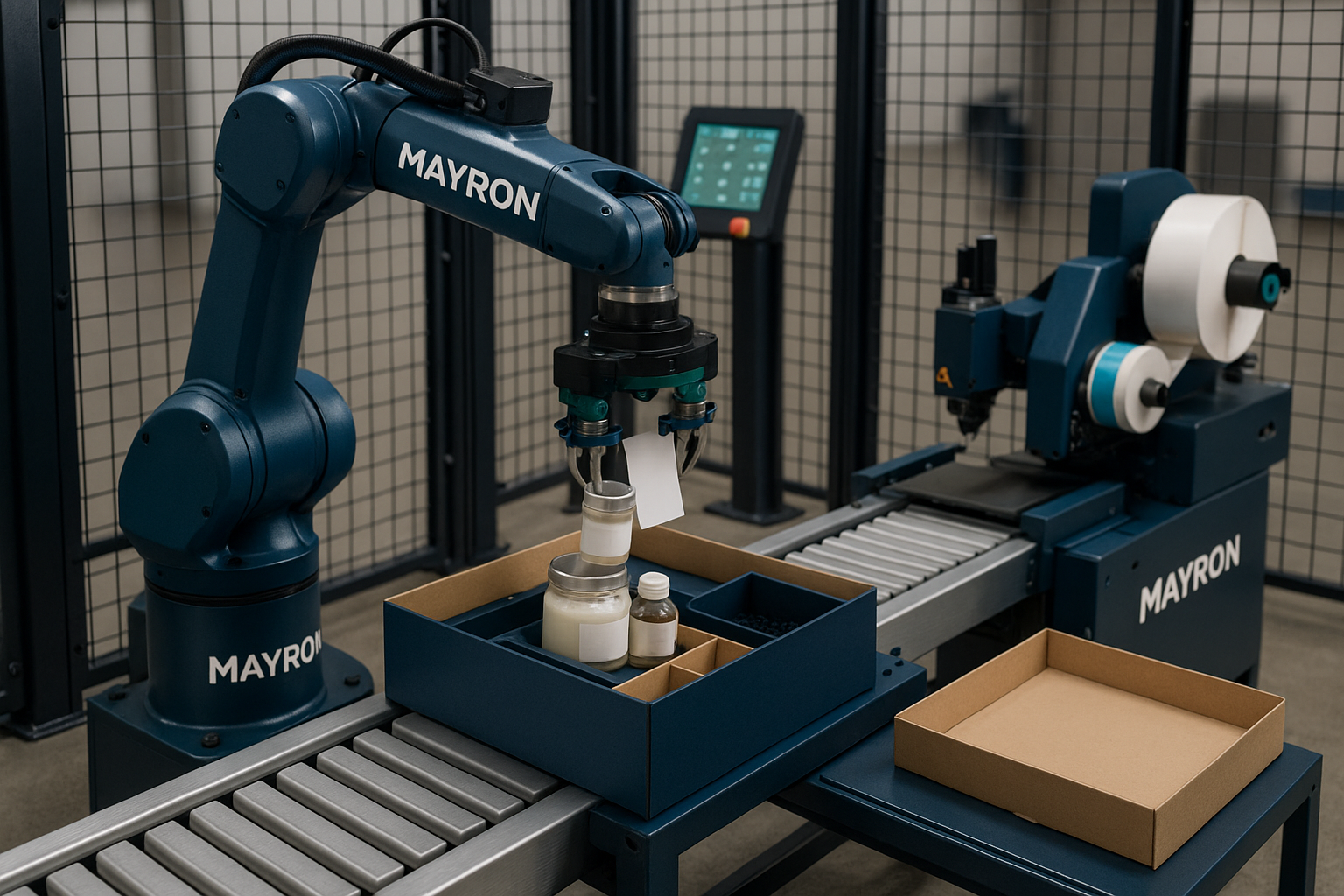

Personal Care Kitting

Automated kitting and cartoning for personal care items with vision verification and gentle handling.

Multi-SKU Sorting Cell

High-speed sorting of mixed consumer SKUs with barcode/vision verification and automatic reject.

Gift Set Packaging Cell

Configurable gift/bundle packaging with recipe-driven changeovers and print-verify labeling.

Defect Detection AI

Real-time AI vision inspection for cosmetic and functional defects with explainable results and automatic rejection.

3D Vision Inspection

High-speed 3D point-cloud inspection for dimensional checks, coplanarity, and complex geometry defects with full traceability.

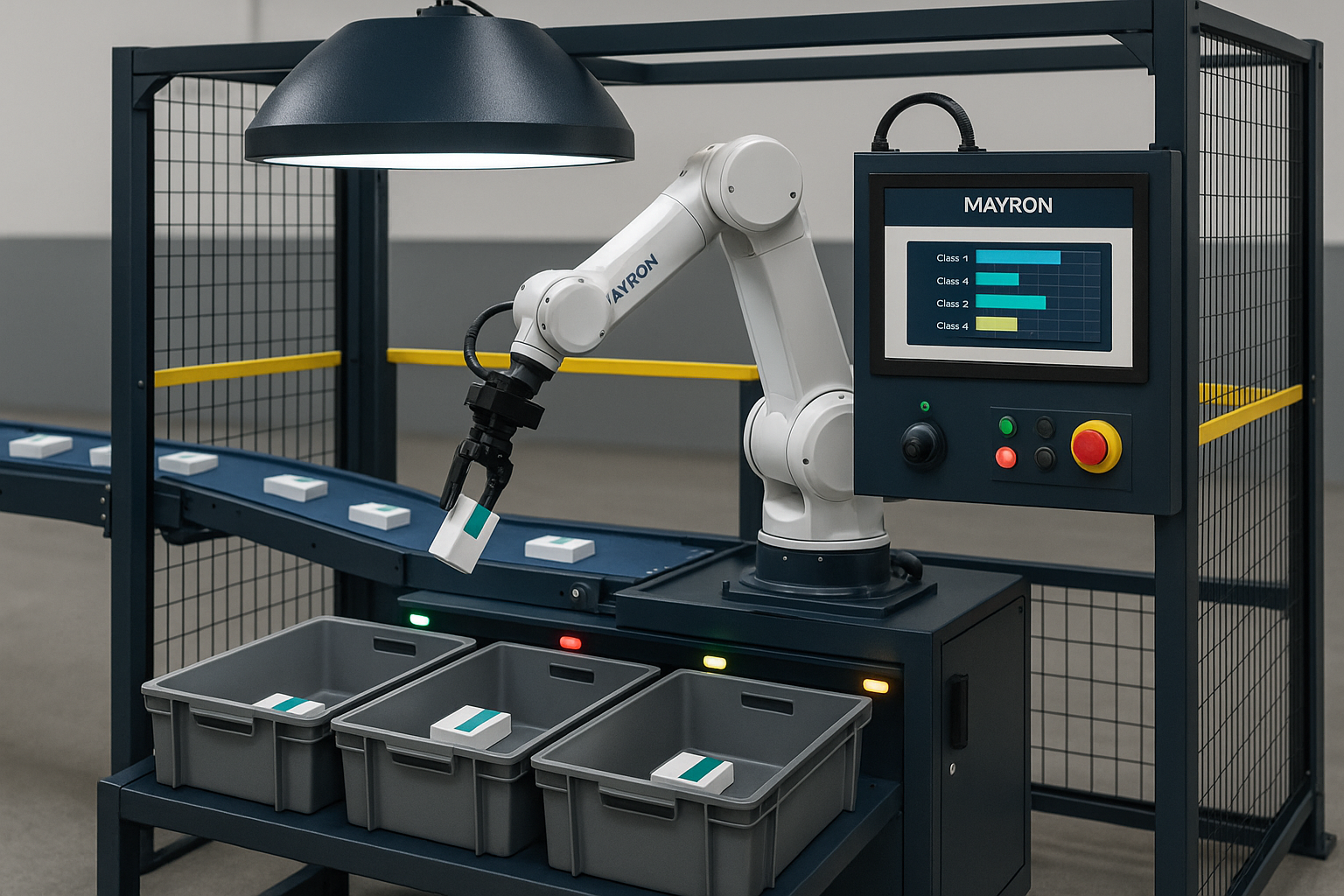

AI Sorting Cell

High-speed AI vision sorting of mixed SKUs with automatic classification, rejection, and binning for lights-out fulfillment.

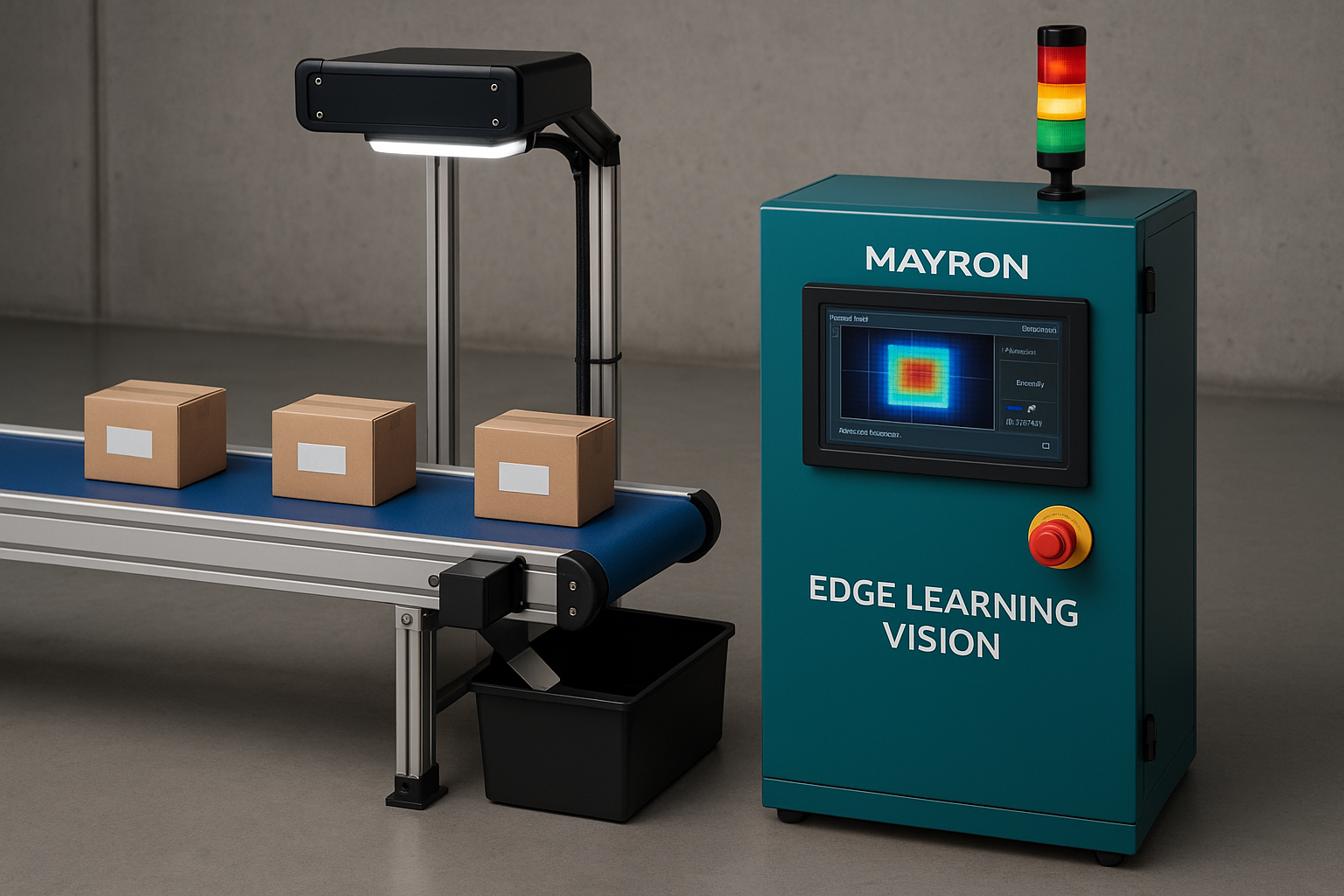

Edge Learning Vision

On-device vision with few-shot learning and supervised continuous improvement at the edge—no cloud latency.

Adaptive Control Cell

Closed-loop robotics that auto-tunes force, speed, and path using vision + force/torque sensors for consistent quality on variable parts.

OCR Verification Cell

Inline OCR/OCV and code verification for lot/exp dates, serialization, and label text—complete with reject and audit logging.

Classification & Tracking Cell

Deep-learning classification with object tracking and auto-sorting to lanes/bins; full audit trail.

Surface Defect Scanning Cell

Area/line-scan inspection for scratches, dents, and finish defects with SPC and reject handling.

Smart Bin Picking (AI)

AI-driven pose estimation and grasp planning for mixed bins; continuous improvement via feedback.

Optical Characterization Cell

Optical tests (color, gloss, reflectance) with recipe-driven setups and auto-calibration.

MIG Welding Cell

Robotic MIG welding with adaptive seam tracking and spatter control inside a Class‑1 enclosure.

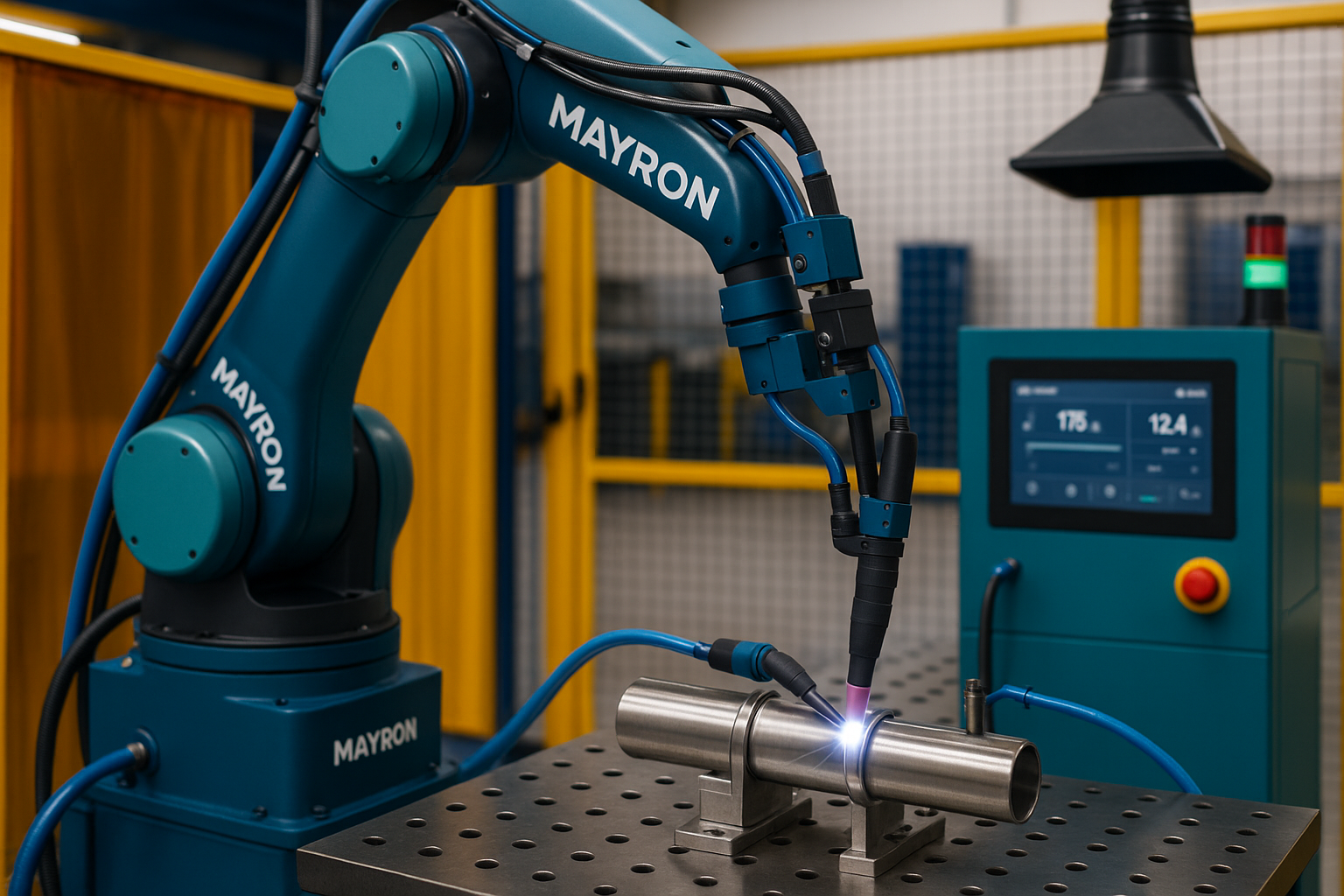

TIG Welding Cell

Precision TIG welding with pulsed current control and gas management for thin materials.

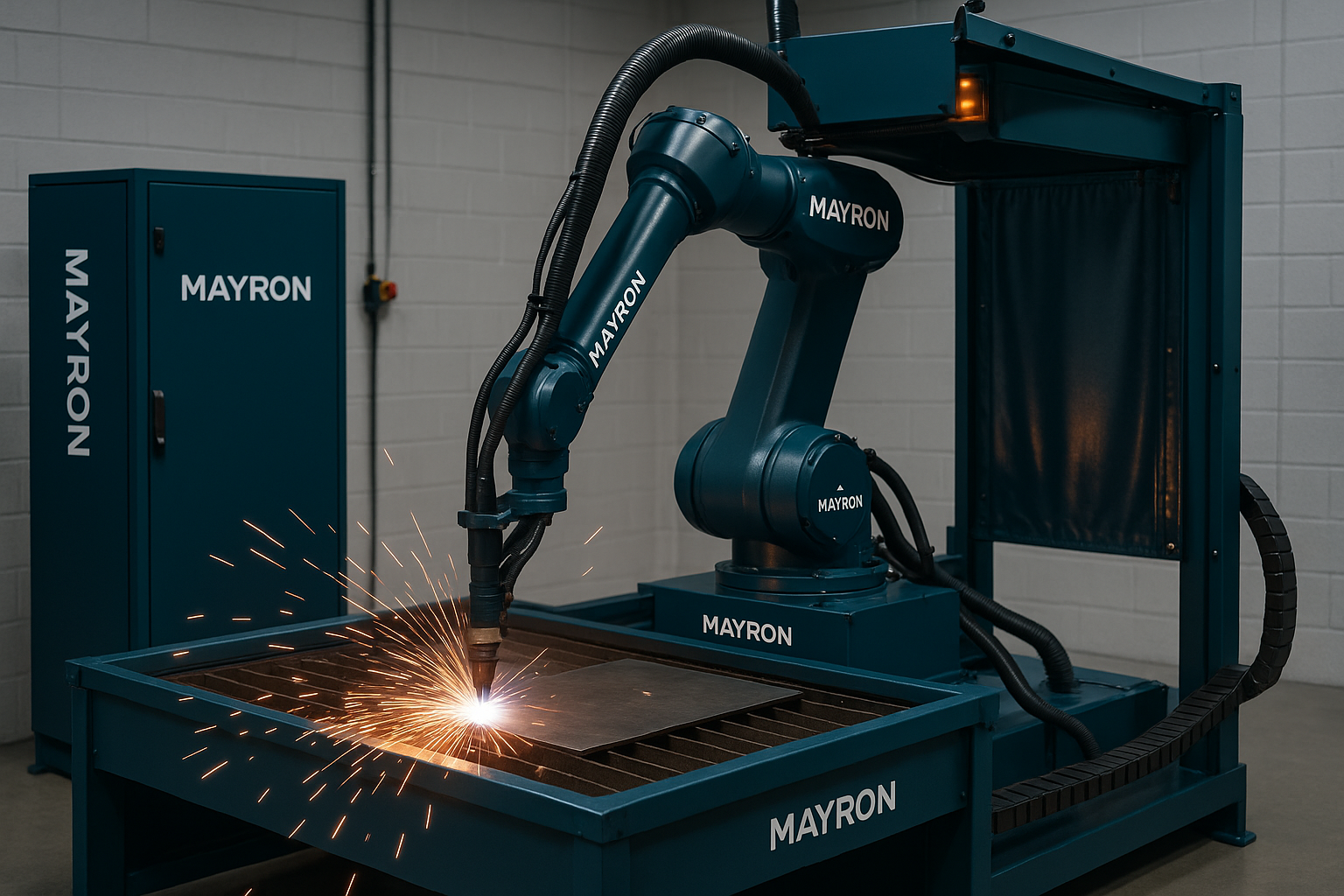

Plasma Cutting Cell

High-speed robotic plasma cutting with torch height control and fume extraction.

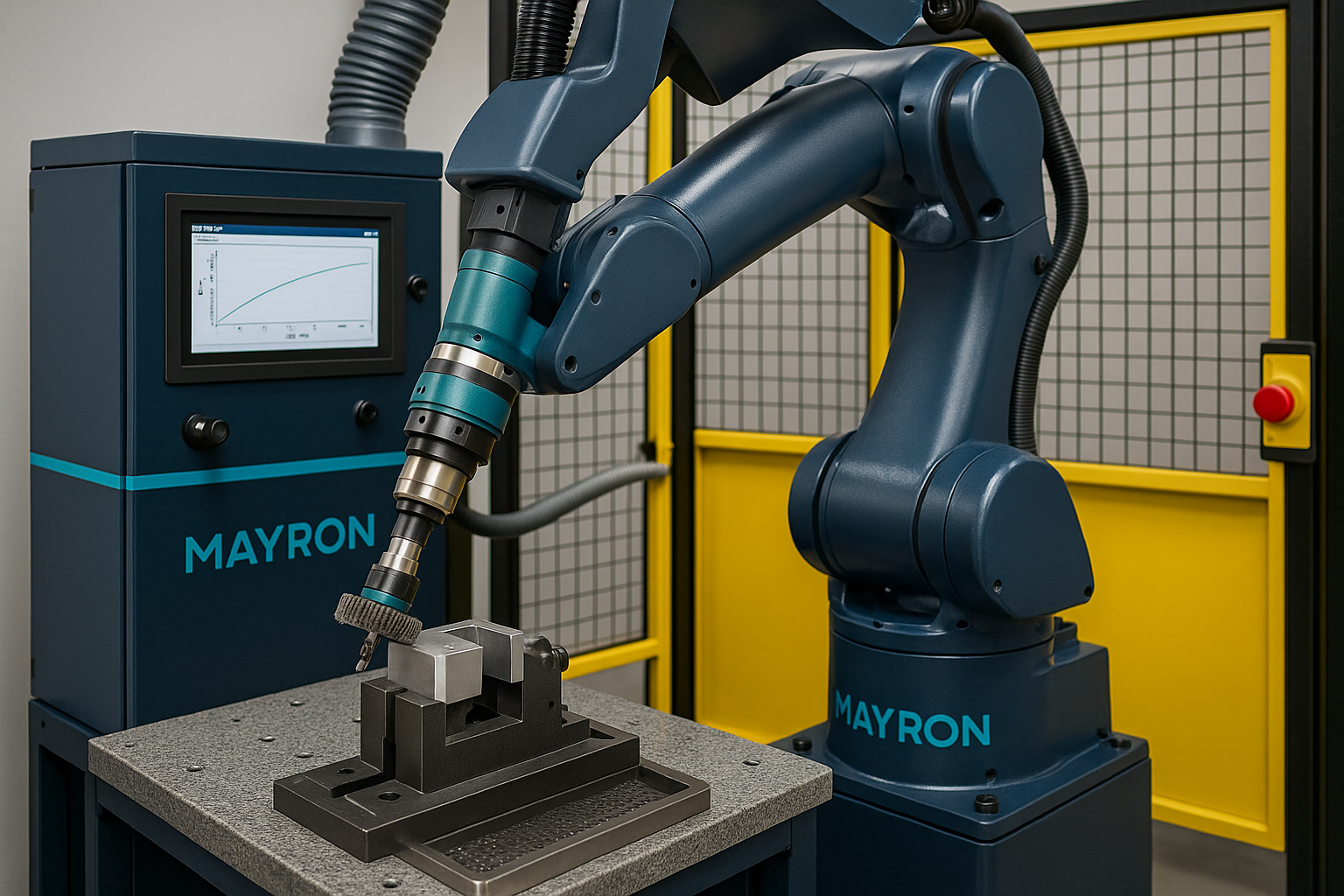

CNC Tending Cell

Automated machine tending for CNC mills/lathes with vision alignment and deburr/pass-through options.

Grinding & Polishing Cell

Automated grinding/polishing with force control, tool wear monitoring, and dust extraction.

Deburring Cell

Robotic edge deburring with adaptive force and toolpath optimization; integrated chip collection.

Laser Welding Cell

High-speed, low-distortion laser welding with adaptive seam tracking and Class‑1 safety enclosure.

Punch Press Cell

Robotic punch press tending with vision alignment, die protection, and automated sheet/part handling.

Robotic Brake Press Cell

Automated sheet-metal bending with precise angle control, scratch-free handling, and consistent throughput.

Friction Stir Welding Cell

Solid-state welding for aluminum and compatible alloys with low distortion, high strength, and clean joints.

Jewelry Handling

Ultra-gentle jewelry handling with precision placement and security features.

Book Palletizing

Automated book palletizing with gentle handling and stack optimization.

Paint Masking

Automated paint masking with precision tape application and trimming.

Textile Folding

Automated textile folding with vision guidance and gentle handling.

Medical Kit Assembly

GMP-ready kitting with 100% verification, print-apply labeling, and full lot/expiry traceability.

Clean Deboxing Cell

Contact-minimized deboxing/unbagging with HEPA downflow and contamination control.

Small Parts Binning Cell

Automated parts counting, binning, and label verification with audit logging.

Electronics Rework Cell

Hot-air + solder rework with vision guidance, ESD protection, and repair traceability.

Sterile Pouch Sealing Cell

Validatable heat sealing with barcode/UDI print-verify and inline peel testing.

Vision-Guided Assembly Cell

Flexible vision-guided assembly with quick-change tooling and SPC logging.

Prototype Cell

Flexible prototyping cell with reconfigurable tooling and quick changeover.

Multi-Purpose Robot Cell

Versatile robot cell with multiple end-effectors and quick changeover capability.

Pick-Pack-Ship Cell

Complete pick-pack-ship automation with order management integration.

Lab Sample Handling

Automated laboratory sample handling with contamination prevention.

Retail Display Assembly

Automated retail display assembly with flexible configuration options.

Battery Assembly

Automated battery assembly with safety monitoring and quality control.

Solar Panel Placement

Precision solar panel placement with alignment control and quality verification.

Automotive Mirror Handler

Specialized automotive mirror handling with gentle grip and quality inspection.

Coffee Packaging

Automated coffee packaging with aroma preservation and quality control.

Multi-Function Flex Cell

Ultimate flexible cell with multiple robots and reconfigurable tooling.

Need a Custom Solution?

Our engineering team can design and build custom automation cells tailored to your specific requirements.